My girlfriends son visits us regularly. We enjoy the visits and what makes it even more fun is that he is a tinkerer just like me. We really had some great fun playing with Oobleck and we made an infinity mirror in a table for his home.

This time he told me he was looking at making a Midi-controller. As we discussed the project talking about the hardware (Arduino) he told me that he was looking for special keys for the controller. He did not want the normal hard keys. He wanted the kind of soft keys most remote controls have. And he wanted keys in different shapes. As he had searched the internet he had not yet found anything to his liking.

My proposal was to make custom keys with Oogoo. Oogoo is a mix of silicon caulk and corn startch like I described in the story you can read by clicking here.

He thought it was a great idea because Oogoo had the right feel for the keys he was looking for. But how to make custom keys with it. Well we would need to make a kind of mold. Easy said. And yes indeed equally easily done. This is a perfect job for a 3D printer.

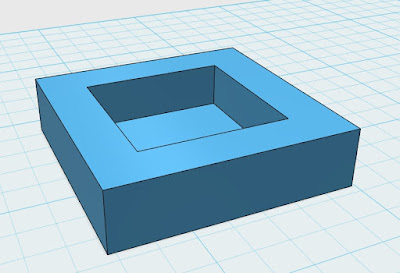

So I started designing a simple square key in 123D-Design.

123D-Design is just like Tinkercad another great free program from Autodesk. Tinkercad is web-based. 123D-Design is a program you download in your computer. All the designs you make with it can be stored on your computer or (like Tinkercad) on the web. 123D-Design has several advantages over Tinkercad. It is faster, as it is not internet dependend, and it has some really nice features that Tinkercad misses. 123D-Design has a bit more steep learning curve for first time users. Therefore I advise to start with Tinkercad until you know all the basics of 3D designing and then switch over to 123D-Design.

When I had finished the prototype key and downloaded the STL-files I set my Beagle 3D printer to work,In the mean time I started to work at the contra-part for the mold. I enlarged the key part a bit and left the base for what it was. I enlarged the key with 2 mm on all four sides. That way they actual key would get walls which would be 2mm thick.

Then drew a solid box. I rotated the key 180 degrees and put it on top of the box but so that the key was positioned in the box and the base on top. Then I subtracted they key from the box and that's all there is to it. The counter part for my mold was ready.

So in about an hour time I had designed AND printed my first prototype.

We mixed up some silicon-caulk and corn-starch until we had a nice thick paste and put it in the molds counterpart and then we pushed the keypart in.

If you look at it it looks like something edible, but believe me it is not !!!!

As it was a nice day, one of the first warm spring days, we took our girlfriends out for a walk and let the Oogoo set.

We were just afraid that we would not get the Oogoo key out of the mold. Maybe it would stick to it and tear apart if we were going to get it out.

But everything went even better as expected. The Oogoo key came niceley loose from the mold without any effort.

And the result is perfect. It is not yet the perfect key we were looking for but it is an ideal prototype. We know we are on the right path.

It even gets better as the Oogoo is transparant. Therefore it not only possible to put a switch beneath it but we can also put a led beneath it. That way we can give the key an extra dimension. All colours give the key that nice extra finishing touch.

A few days after his visit I started experimenting further. And indeed it is possible to make all kinds of shapes for the keys. As the example demonstrates I can make round keys.

I even filled a box with Oogoo to see if that would work and yes I got a nice bar out of it.

What does this demonstrate.

It is obvious that Oogoo is a versatile material and suitable to make keys with for all kinds of projects. But this also demonstrates that it is really easy to design molds, print them in PLA and use them and re-use them. The Oogoo comes out of the mold easily and without damages.

I bet I even can make stamps and badges with Oogoo and someone suggested making anti vibration feet for a 3D printer. So go on, make your own christmass decorations or use your imagination and make ........

Have fun

Till next time

Luc Volders

Thursday, December 15, 2016

Thursday, December 1, 2016

Check Check and Doublecheck !!!

One of my projects was nicely coming along. In reality it was just a stupid project being a portable thermometer using an ESP8266 that displays the temperature on a web-page. So nothing special. The breadboard version worked like a charm to I transferred it to some stripboard. And then disaster struck.

It just did not work. The dreaded blue smoke materialised and my ESP was fried !!! Damn what happened ???

So I checked my stripboard soldering over and over and I just couldn't find a fault. There was only one thing left to do: check the power supply.

My intention was getting power from a USB power source be it from a computer or a power bank.

For that reason I use cheap USB power cables from the dollar store. I cut the cable and strip the wires.

The wires are colored just like they need to be: Black for ground, Red for VCC Green and White for the USB data channels.

I hooked up a mulimeter and it looked allright. 4.9 volts is great. But hey look at that closely. It does not say 4.9 volt !!! It says - 4.9 volt.

So I took out my trusted polarity checker (find the sory on that by CLICKING HERE) and hooked it up. Black to Black and Red to Red. And then it was obvious. The red light was on. Polarity was reversed !!!!

And then I switched the power leads: Red on Black and Black on Red and there it was: the blue led went on: everyting. ok.

So there you have it: the color of the power leads from the USB cable were reversed. The GND was on the RED cable and the VCC on the black cable !!!! Some idiot in the factory switched the colors of the cable. Everything on the connector side was ok, just the colors of the cable had been switched.

So before you hook anything up:, NEVER TAKE ANYTHING FOR GRANTED and CHECK !!!! Check !!!! CHECK and DOUBLECHECK !!!

This is the first time I say in my web-log: this was no fun at all.

Till next time.

Luc Volders

P.S. Check and Doublecheck !!!

It just did not work. The dreaded blue smoke materialised and my ESP was fried !!! Damn what happened ???

So I checked my stripboard soldering over and over and I just couldn't find a fault. There was only one thing left to do: check the power supply.

My intention was getting power from a USB power source be it from a computer or a power bank.

For that reason I use cheap USB power cables from the dollar store. I cut the cable and strip the wires.

The wires are colored just like they need to be: Black for ground, Red for VCC Green and White for the USB data channels.

I hooked up a mulimeter and it looked allright. 4.9 volts is great. But hey look at that closely. It does not say 4.9 volt !!! It says - 4.9 volt.

So I took out my trusted polarity checker (find the sory on that by CLICKING HERE) and hooked it up. Black to Black and Red to Red. And then it was obvious. The red light was on. Polarity was reversed !!!!

And then I switched the power leads: Red on Black and Black on Red and there it was: the blue led went on: everyting. ok.

So there you have it: the color of the power leads from the USB cable were reversed. The GND was on the RED cable and the VCC on the black cable !!!! Some idiot in the factory switched the colors of the cable. Everything on the connector side was ok, just the colors of the cable had been switched.

So before you hook anything up:, NEVER TAKE ANYTHING FOR GRANTED and CHECK !!!! Check !!!! CHECK and DOUBLECHECK !!!

This is the first time I say in my web-log: this was no fun at all.

Till next time.

Luc Volders

P.S. Check and Doublecheck !!!

Labels:

Electronics,

Various

Subscribe to:

Comments (Atom)